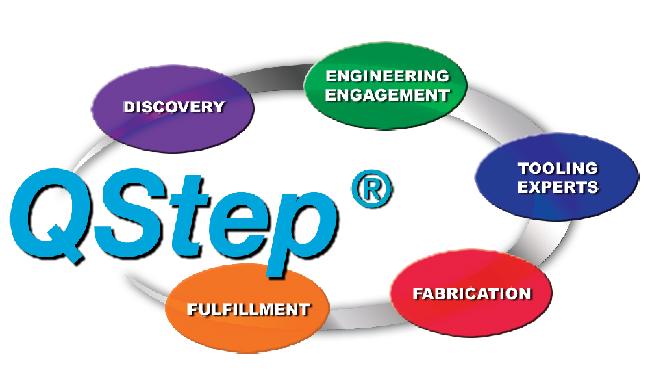

Versatility’s lean manufacturing culture emphasizes partnerships with our customers, vendors, and academia. Engineering personnel use QStep®, our customer engagement process, to drive a project's success by positively impacting quality, cost, and delivery. Versatility Tool Works strives to be a true business partner by offering precision metal fabrication along with a spectrum of value-added services including tooling, design, engineering, state of the art manufacturing, and inventory fulfillment.

Heavy Duty Cabinets and Carts

Versatility Professional Tool Storage Products have been designed, as well as lean manufactured, to help industrial manufacturers and fabricators, commercial business and mechanics and motorsport specialists from the high-performance industry compliment "Lean" and "5S" initiatives.

Versatility Professional Tool Storage Products have been designed, as well as lean manufactured, to help industrial manufacturers and fabricators, commercial business and mechanics and motorsport specialists from the high-performance industry compliment "Lean" and "5S" initiatives.

By engaging with customers from design, to order to delivery – they access our advanced engineering, tooling, design manufacturing, automated sheet fabrication, assembly and fulfillment programs. The result is that Versatility Professional Tool Storage customers experience a unique combination of service and technological innovation that drives quality, optimal cost, best delivery, and ultimately, the success of the customer.

The QStep process has a demonstrated history of adding value to our customer's relationships by positively impacting quality, cost, product performance, and delivery. The QStep Process, when combined with Versatility’s Tool Work’s engineering expertise, cutting-edge design and manufacturing technology, provide each customer the best storage cabinet and cart solutions.

40 Years of Product Line Research and Development

Innovative Design and Engineering

Unsurpassed Quality and Durability

World Class Quality Control

Customer Service and Collaboration